Novidrill-3 Series - NEW!!!!

New page under construction

NOVIDRILL - 3th Generation Electro erosion drilling machines

Special for Hard Materials

| Model | Novidrill 400-III(NEW) | Novidrill 500-III(NEW) | |

|---|---|---|---|

| Work Table size (L x W) | mm | 400 x 600 | 440 x 630 |

| Travel of Working Table (manual) | mm | 300 x 400 | 400 x 500 |

| Axes travel Z axis | mm | 400 | 400 |

| Axes travel W axis | mm | 350 | 350 |

| Distance director to Work Table | mm | 85 – 435 | 235-585 |

| Max. machining current | A | 30 | 30 |

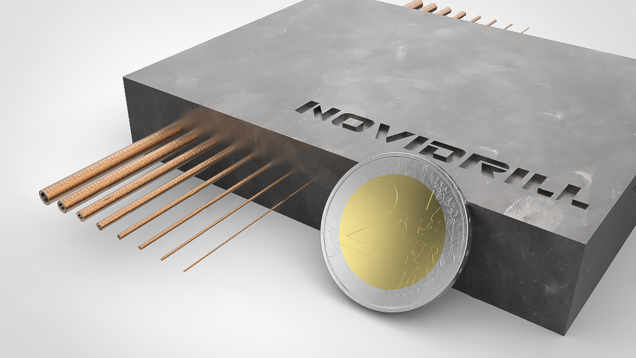

| Electrode diameter | mm | Ø0.3 – Ø3.0 | Ø0.3 – Ø3.0 |

| Optional minimum diameter | mm | 0,1 | 0,1 |

| Optional maximum diameter | mm | 6.0 | 6.0 |

| Max. load on Work Table | kg | 200 | 300 |

| Working liquid | - | Water or dielectric fluid | Water or dielectric fluid |

| Power supply | - | 380V / 50 Hz | 380V / 50 Hz |

| Total input power | KVA | 3.5 | 3,5 |

| Overall dimensions | mm | 1060 x 1050 x 1680 | 1250 x 1150 x 2100 |

| Weight | kg | 865 | 975 |

| Digital display | 0.001mm | Three axes digital | Three axes digital |

Novidrill 3 Series

Build with experience - Master in Hard materials

Granite Table : SOO MUCH BETTER !!!

Granite Table Standard

Big advantages:

Can not drill in the table

Table resist to corrosion of the dielectricum (drilling liquid)

Don't get rusty

Keeps the super precision in time and guarantees a better flatness

Parts can not be welded to the table due to electrical current through the contact surface with table

High speed drilling with reduced bullet nosing

- Novidrill 400/500-III uses the proven unique pneumatic activated high pressure (70 – 120 bar) coolant/dielectric/water pump. The combination of the super high-pressure dielectric fluid, the rotation of the tubular electrode and the high electrode feed rate (controlled by a fast response servo) make it possible to produce holes at a very fast rate and of very small dimensions (till 0,2mm diameter)

- High pressure dielectric fluid is one of the most important factors, which is usually supplied to the gap through the bore of tubular electrodes.

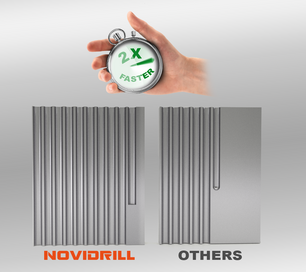

- The use of our pneumatic intensifier pump results in drilling parts up to 50% faster and with lower operating costs as much as 40%! Our high-pressure pump produces 30% more pressure than a standard water jet pressure pump, resulting in a 40-50% increase in productivity for many materials. Compared to a water jet pump, typical operating pressures uses 30% less water, 30% less power, and up to 50% less electrode consumption, resulting in a 40% reduction in operating costs. Being green with energy does not only spare the nature but also your wallet.

- Auxiliary Flush provides continuous cleaning of die guide and work piece and aids electrode entry and breakthrough.

- peed and simplicity

- Drilling rates up to 1,2 mm/second can be achieved and obtainable hole sizes are between 0.2 and 3mm, with a length-to-diameter ratio of over 150:1. The process can be applied in the production of a variety of parts including fuel injectors, cutting tools, medical equipment, start holes for wire cut and more.

- Factors including the generator (electrical parameters), electrode geometry and most important, the dielectric flushing are very important for the correct EDM process. Drilling time and electrode wear can be reduced by 85 % and 45% respectively, depending on the type of electrode geometry used and pressure of coolant applied.

Most economical high speed drilling machines

Considered a last resort for drilling holes, Fast Hole Electrical Discharge Machining (EDM) Drilling is quickly becoming the standard method for producing small, tight tolerance holes. It is an extremely cost-effective method for producing fast and accurate holes into all sorts of whether hard or soft conductive materials. EDM drilling operates on the principal of eroding material via the use of electric energy.

There are many advantages of using fast EDM drilling versus conventional drilling:

- Some materials are too hard to drill using conventional methods. The EDM machine drills through almost any conductive material including carbide and hardened steel.

- Drills tend to bend in contact with the surfaces. To prevent this, additional fixtures and guide bushings must be used. With EDM drilling, the electrode never contacts the material being cut, thus eliminating the tool pressure normally experienced when drilling on curved or angled surfaces.

- Deburring holes drilled by conventional methods can take longer than the drilling. EDM drilling creates no burrs. This burr-free drilling saves time and labor and is especially crucial when difficult holes are being drilled. In addition, surface finishes are better. The smaller the hole, the more important a smooth surface is.

- Drilling holes with conventional methods is often extremely difficult if not impossible. EDM drilling is often the only practical method for producing such holes.

- As conventional drills enter or exit, they can break if torque is not carefully controlled. Small broken drills are often difficult to remove from the work piece, and time is wasted replacing broken drills and parts may have to be scrapped. With EDM drilling, torque conditions do not exist since the electrode never contacts the workpiece.

If required close tolerance, small holes EDM drilling is "the" technology to utilize. By reducing the discharge energy, holes can be polished.

This machine can be used not only to drill precise holes in medical and dental instruments, but its applications has such a wide variety and even includes drilling holes in rocket turbine blades, fuel injectors, cutting tool coolant holes, hardened punch ejector holes, plastic mold ventholes, and starter holes for wire EDM.

High Speed drilling

We drill faster than the others!

Waterjet High pressure pump 120 Bar max

- Novidrill-II uses a unique pneumatic activated high pressure (70 – 120 bar) coolant/dielectric/water pump. The combination of the super high-pressure dielectric fluid, the rotation of the tubular electrode and the high electrode feed rate (controlled by a fast response servo) make it possible to produce holes at a very fast rate and of very small dimensions (till 0,2mm diameter)

- High pressure dielectric fluid is one of the most important factors, which is usually supplied to the gap through the bore of tubular electrodes.

- The use of our pneumatic intensifier pump results in drilling parts up to 50% faster and with lower operating costs as much as 40%! Our high-pressure pump produces 30% more pressure than a standard water jet pressure pump, resulting in a 40-50% increase in productivity for many materials. Compared to a water jet pump, typical operating pressures uses 30% less water, 30% less power, and up to 50% less electrode consumption, resulting in a 40% reduction in operating costs. Being green with energy does not only spare the nature but also your wallet.

- Auxiliary Flush provides continuous cleaning of die guide and work piece and aids electrode entry and breakthrough.

- Drilling rates up to 1mm/second can be achieved and obtainable hole sizes are between 0.2 and 3mm, with a length-to-diameter ratio of over 300:1. The process can be applied in the production of a variety of parts including fuel injectors, cutting tools, medical equipment, start holes for wire cut and more.

- Factors including the generator (electrical parameters), electrode geometry and most important, the dielectric flushing are very important for the correct EDM process. Drilling time and electrode wear can be reduced by 85 % and 45% respectively, depending on the type of electrode geometry used and pressure of coolant applied.